Liquid Vinyl Siding™ is not an ordinary paint, it's in a class by itself. It is composed of virgin vinyl resin, an expensive component not commonly found in other coatings. Using a complex manufacturing process, Liquid Vinyl Siding™ is made by suspending vinyl resins and copolymer in an acrylic emulsion using emulsion polymerization. Other quality components that are added provide the coating with some very beneficial properties. Titanium dioxide, a crystal that reflects heat causing rays from the sun, is added to enhance energy efficiency, stabilize color and increase the tensile strength of the vinyl film. Other components are added to the formulation to inhibit growth of mold and mildew, reduce chalking and in general, make the vinyl coating tougher and more resilient. The combination of unique components contained in Liquid Vinyl Siding™ enable this exceptional coating to provides a higher level of protection and performance than paint and other coatings.

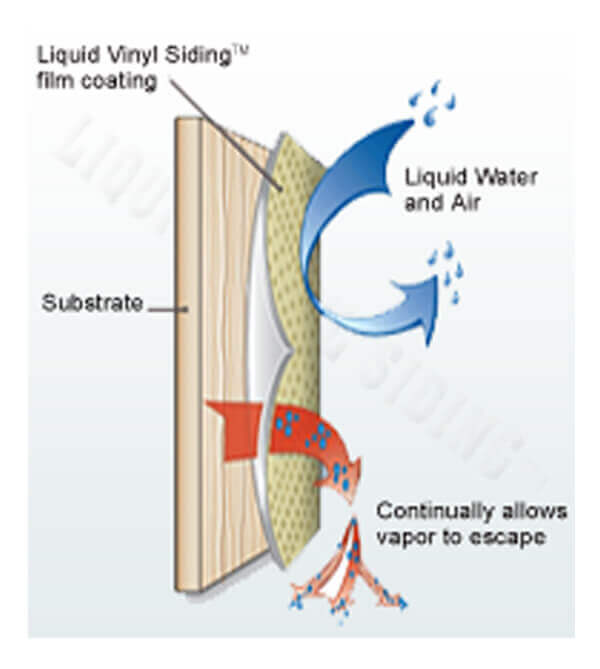

The vinyl particles contained in the coating creates breatheability and enables the film membrane to shed water. As the wet coating dries, solid matter suspended in the emulsion migrates through the liquid portion and aligns in a specific pattern as the dry vinyl film forms. Vinyl particles are spherical in shape with rounded edges. They compresses somewhat as the film dries but still retains its roundness that leaves minuscule gaps between particles. These gaps turn out to be very beneficial by creating a mechanism for vaporized moisture to escape. Small vapor particles are able to squeeze between the gaps and pass through the coating film whereas water molecules (much larger in size) are unable to penetrate the spaces. This creates a breatheable membrane with the ability to shed water. Liquid Vinyl Siding™ is highly permeable with a rating of 15.3 perms.

EMULSION POLYMERIZATION PROCESS - Emulsifiers are used to disperse vinyl chloride monomer in water.

Emulsion polymerization produces very fine non-porous grains in the range of 1 micron creating the advantage of a coating without a

graininess surface. Surfactants are used in the polymerization of vinyl chloride to increase the surface tension and conductivity until it

reaches the critical micelle concentration (c.m.c). At this stage, the emulsified molecules organize in way that their hydrophilic groups

are at the outer space contacting with water and hydrophobic groups are gathered inside the micelle. Most of the vinyl chloride monomer

droplets get dispersed in the micelle using water soluble free radical initiators.

The Perm Rate is defined as the 'RATE OF FLOW OF A GASEOUS LIQUID THROUGH A POROUS MATERIAL'. ( also referred

to as permeability or breathe ability)

The scientific measurement is 1 grain of water vapor per hour, per square foot, per inch of mercury measured in units called PERMS.

1 US Perm (0.659045 Metric) = 57.2135 ng.s‑1.m‑2.Pa‑1