In a Class by Itself and Unlike Any Other Coating

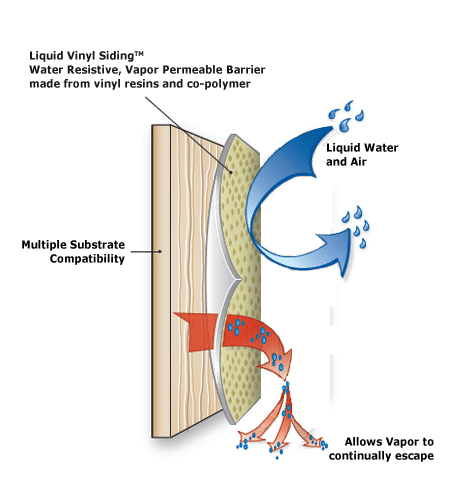

What makes Liquid Vinyl Siding™ truly unique is its chemical composition.

Unlike other exterior coatings, it is composed of co-polymer and virgin vinyl resins, a similar material

used to make vinyl siding panels. The solid particles are suspended in an acrylic emulsion using a

process called emulsion polymerization. To enhance overall

performance other components are mixed. One such component is titanium dioxide (TiCO²), a bright

white crystal that reflects heat causing rays from the sun to prevent color fading and improve energy

efficiency. Due to its high cost titanium dioxide crystals are not commonly used in ordinary paint.

Components that reduce chalking and inhibit mold and mildew growth are mixed into the emulsion.

Combined, these components make Liquid Vinyl Siding vastly superior to paint and one of the Longest

Lasting coatings you will find.

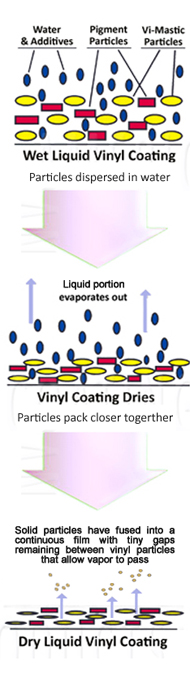

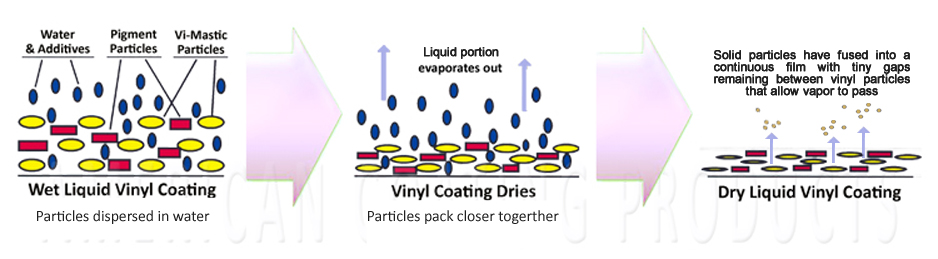

The high concentration of vinyl resins gives Liquid Vinyl Coating several

unique properties. Vinyl particles are spherical. During the curing process, the solid matter

suspended in the wet emulsion migrates and aligns in a specific pattern. Because of the rounded

edges of these resins, natural gaps remain between the particles.

These minuscule gaps are highly beneficial; they create permeability in the vinyl film, providing

a path for trapped moisture to escape. When infrared and ultraviolet rays hit a wall, liquid

moisture vaporizes into fast-moving gaseous particles. As the sun draws this vapor toward the

warmer exterior, the particles continuously bombard the back of the coating. If moisture is unable

to escape, it will eventually cause traditional paint to blister, crack, and peel. However, vapor

particles are small enough to pass through the gaps in the Liquid Vinyl film. Because a liquid water

molecule is significantly larger than a vapor particle, water cannot penetrate these spaces from

the outside. This allows Liquid Vinyl to repel exterior water while remaining highly breathable‑much

like Gore‑Tex® fabric.

Liquid Vinyl Siding has an amazingly high perm rate. It's permeability

is rated at 15.3 which is surprisingly high for a breatheable coating.

EMULSION POLYMERIZATION PROCESS - Emulsifiers are used to disperse vinyl chloride monomer in water.

Emulsion polymerization produces very fine non-porous grains in the range of 1 micron creating the advantage of a coating without a

graininess surface. Surfactants are used in the polymerization of vinyl chloride to increase the surface tension and conductivity until it

reaches the critical micelle concentration (c.m.c). At this stage, the emulsified molecules organize in way that their hydrophilic groups

are at the outer space contacting with water and hydrophobic groups are gathered inside the micelle. Most of the vinyl chloride monomer

droplets get dispersed in the micelle using water soluble free radical initiators.

The Perm Rate is defined as the 'RATE OF FLOW OF A GASEOUS LIQUID THROUGH A POROUS MATERIAL'. ( also referred

to as permeability or breathe ability)

The scientific measurement is 1 grain of water vapor per hour, per square foot, per inch of mercury measured in units called PERMS.

1 US Perm (0.659045 Metric) = 57.2135 ng.s‑1.m‑2.Pa‑1